Mechanical Workshop

Workshop is a place where skills can be developed. The areas such as fitting, carpentry, welding machining, smithy can help me to check my theoretical knowledge learnt in classroom. Mechanical workshop which transform any innovative concept into reality and helped in every step of the process from design & analysis to the manufacturing and production process. As the technologies are advancing it is essential that the industries will be looking for engineers who can work on these innovative technologies and give solutions.

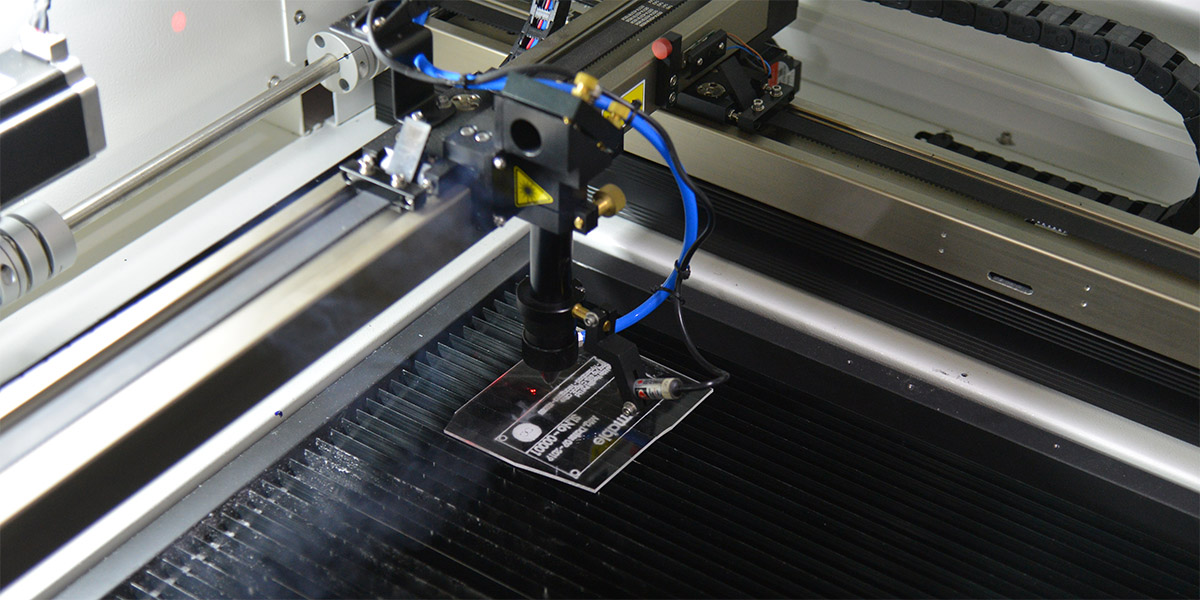

Laser cutting machine (Plastic): Laser cutting machines are a tool used in a wide range of industries for precision cutting and designing projects. The laser-cutting machine emits a high-powered laser beam to either cleanly cut or etch a specific design on materials such as plastic or wood. Specifications:80W, 600x400mm working speed 0-30m/min

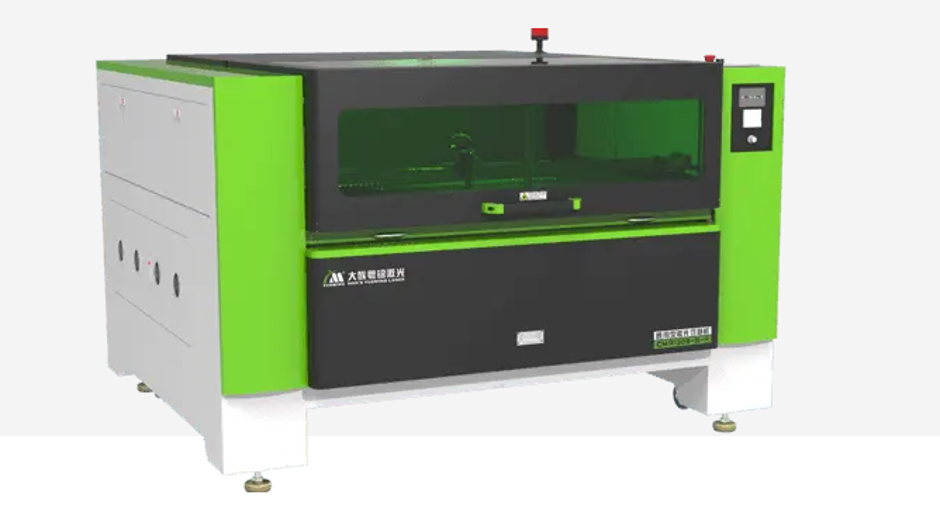

Laser Cutting machine (Metal): Laser cutting machines are a tool used in a wide range of industries for precision cutting and designing projects. The laser-cutting machine emits a high-powered laser beam to either cleanly cut or etch a specific design on materials such as steel, plastic or wood. Specifications: bed 1500mmx3000mm laser source: Raycus laser source

Metal forming machine: forming is the fashioning of metal parts and objects through mechanical deformation, the work piece is reshaped without adding or removing material, and its mass remains unchanged. Specifications: main capacity 75Ton, table size 700x700mm stroke 400mm

Vacuum forming machine: Vacuum forming is a simplified version of thermoforming, where a sheet of material is heated to a forming temperature, stretched onto a single-surface mold, and forced against the mold by a vacuum. Specifications: mold size 300x300x300mm , Oven -30 to 100℃

Laser welding machine: Laser welding is a welding technique used to join pieces of metal with a laser. The beam provides a concentrated heat source, allowing for narrow, deep welds and high welding rates. The process is frequently used in high volume and precision requiring applications using automation, as in the automotive and aeronautics industries. Specification: laser power 1.5kw, Focus length – 100mm, Nozzle aperture – 4mm, fiber length – 10 meter.

Ultrasonic welding machine: Ultrasonic welding is an industrial process whereby high-frequency ultrasonic acoustic vibrations are locally applied to work pieces being held together under pressure to create a solid-state weld. Specifications: Hand Gun device with 40Khz and 500 watt

3D Scanner: 3D scanning is the process of analyzing a real-world object or environment to collect data on its shape and possibly its appearance. The collected data can be used to construct digital 3D models. Specifications; HD Camera, handheld and multiutility, .stl,.obj are output formats

Wire- Cut EDM: Wire EDM machining (Electrical Discharge Machining) is an electro thermal production process where a thin single strand metal wire, along with de-ionized water allows the wire to cut through metal by the use of heat from electrical sparks, while preventing rust. Specifications : 4 axis CNC controlled system, cutting speed – 100mm2/min, wire dia 0.25mm, USB interface

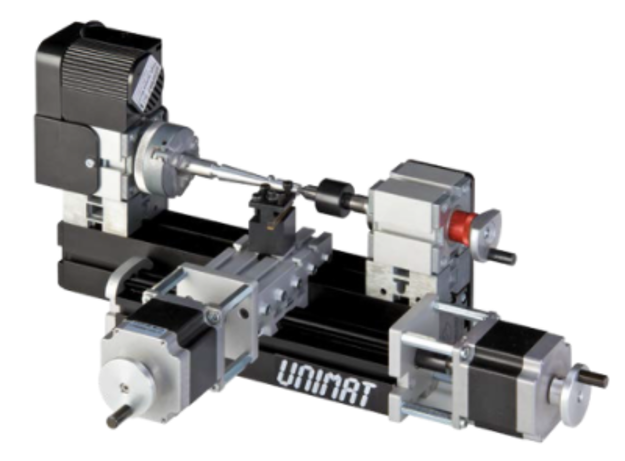

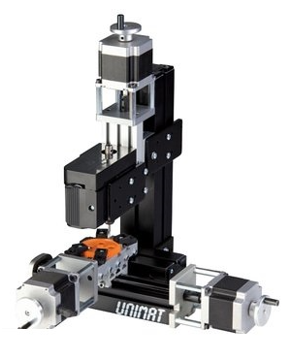

Unimat CNC milling machine: Milling is the process of machining using rotary cutters to remove material by advancing a cutter into a work piece. This may be done by varying direction. Milling covers a wide variety of different operations and machines, on scales from small individual parts to large, heavy-duty gang milling operations. It is one of the most commonly used processes for machining custom parts to precise tolerances. Specifications: CNC-Axe – 3, Drive -Steppers, 2A, 1.8°Max, positioning speed – 300 mm/min, Travels Z/Y – 50 mm (expandable)/50mm, Travel X-axis – 145mm, Accuracy 0.07 mm, Head spindle 4000 rpm, with 1/8" collet

Unimat Lathe machine: A lathe is a machine tool that rotates a workpiece about an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, deformation, facing, and turning, with tools that are applied to the workpiece to create an object with symmetry about that axis. Specification: center height of 50 mm, With the 3-jaw chuck work pieces, 56 mm (inside) and 65 mm (outside) can be clamped, Travel: Z-axis 145 mm, X-axis 32 mm

Mayku forming machine: Specifications: Height- 466mm, Forming bed- 200mm (L) × 200mm(W) x 130mm (H), Temp range of the built-in heater is 160C – 340C, PETg, HIPS, ABS, Polystyrene, Polypropylene, Polycarbonate, Polyethylene, Acrylic PMMA

Huan Yeming Acrylic Laser Cutter

Huan Yeming Acrylic Laser Cutter is use for both cutting and engraving acrylic sheets. It uses Smart Carver controller which is based on advanced 32bit DSP technology, improving the performance greatly. Stable S-type variable-speed controller software design ensures fast and stable running, and makes perfect cutting results by coordinating with auto laser compensation technology.

Working area – 600 mm x 400 mm

Thickness of acrylic sheets – 2mm , 3mm and 5mm acrylic sheet as input.

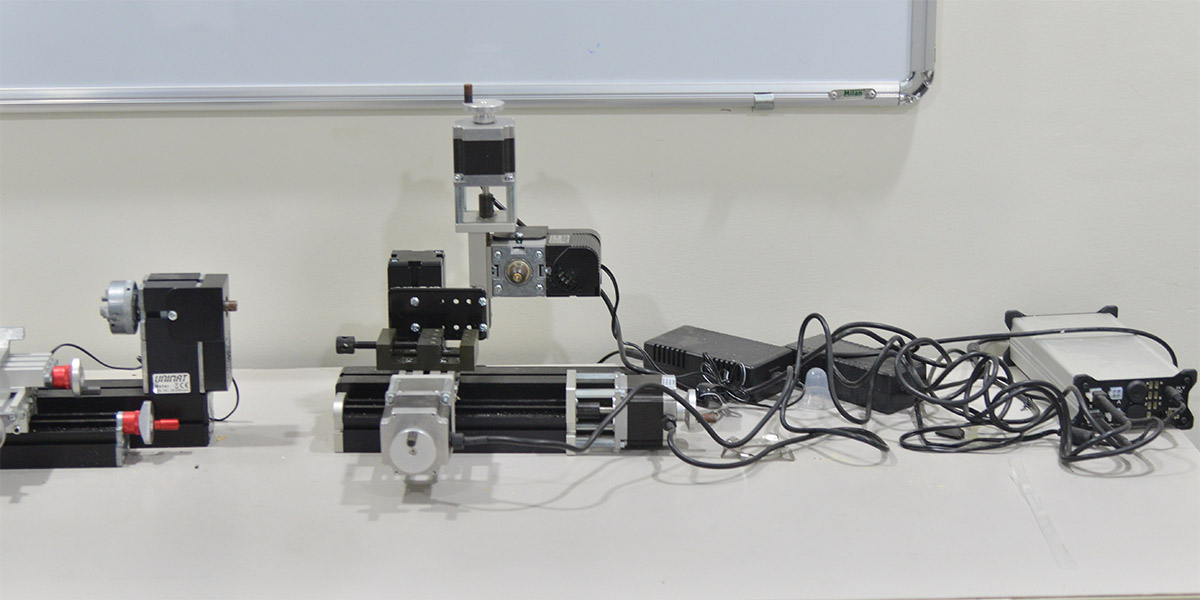

Unimate Lathe

With distance between centres of 90 mm (optionally expandable), centre height of 50 mm and equipped with a two-position tool post. Aluminium,

brass, copper and other materials can be processed precisely. With the 3-jaw chuck work pieces with diameters up to 56 mm (internal) and 65 mm external) can be clamped.

Travel:

Z-axis 145 mm

X-axis 32 mm

Unimate CNC Mill

Using 3 slides it allows processing work pieces 3-dimensionally.

Travel:

X-axis 145 mm,

Y and Z-axis 32 mm

Collets with a clamping range from 1 to 6 mm.

Other Ancillary Mechanical Equipments

Other ancillary hand held Mechanical equipment contains Drill, Jig saw, die grinder, DeWalt Heat gun, Angle grinder and blower which are capable of handling day to day machining operations on wood, acrylics and soft metals.